vITREOUS ENAMEL PROCESS

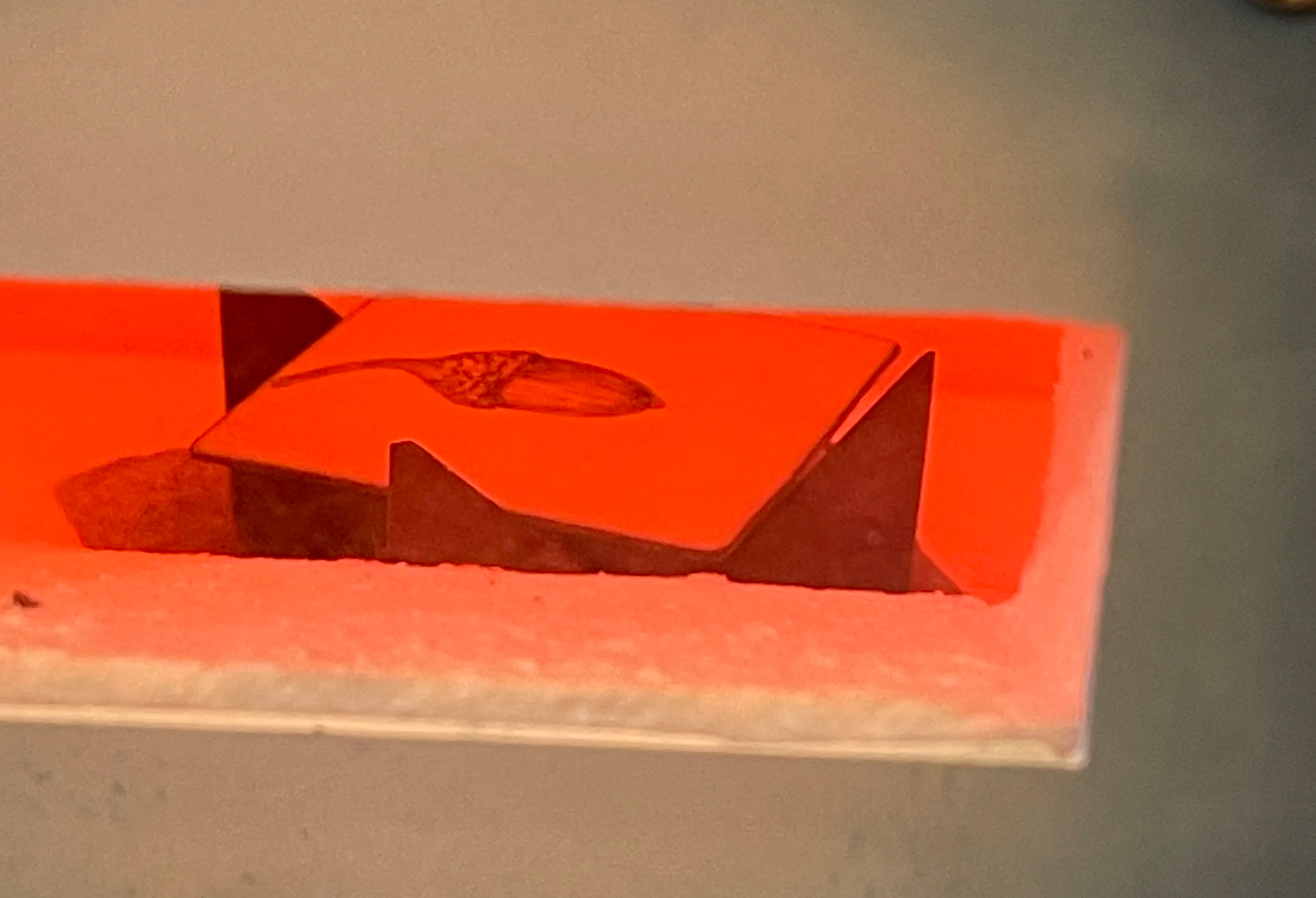

Vitreous enamel is the art of fusing glass to metal at high heat, around 1500°F (815°C). I begin with a bare copper sheet, forming it and applying multiple layers of sifted enamel to the front and back—firing each side once to establish a strong, balanced base. This is done multiple times.

Once that foundation is set, I start building up layers—one color at a time—adding sifted enamel and hand-drawn elements. After each addition, the piece returns to the kiln. This process repeats throughout the day.

Each piece becomes a dance. I respond to what the kiln is doing, and Fuego (the kiln) responds to what I do in return. This back-and-forth creates a one-of-a-kind work—something that truly comes alive.